FB-42 FRICTION BOLT (Friction Stabilizer)

FB-42 SPLIT SET BOLT

As an alternative friction bolt stabilizer of FB-47 Split Set Bolt used in applications, Dia.42mm has the same C shape of bolt body which can also offer a perfect and safety way for ground support as the FB-47 bolt does, also widely and popular used in rock and ground support in mining, tunnel and slope projects etc.

By using the same high tensile steel strip with FB-39 Split Set Bolt to make the FB-42 split set bolt, we adjust our rollformer to change the diameter of bolt slightly from 39mm to 42mm to meet any special requirements of different customers, to be sure our bolt can be used in different environment of projects, meanwhile to satisfy the requirements of our customers.

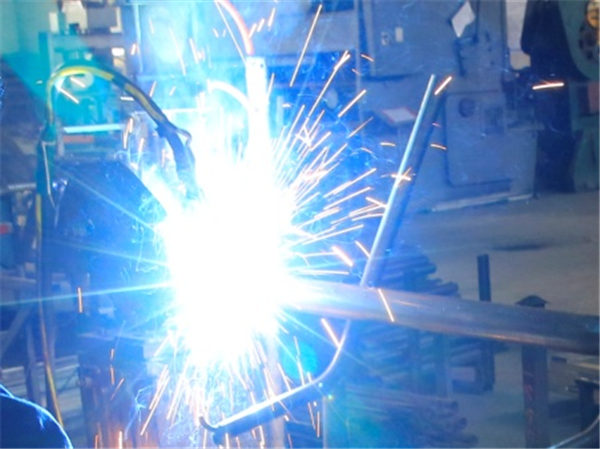

Our high-effective PLC-Controled Rollformer and Auto Welders can keep our production capacity staying in top ranking in this line, at the same time to make sure the quality of our Split Set Bolt to meet the first class international standard requirements, that let us to have an chance to supply our split set bolts (friction bolt stabilizers) to many famous customers in the world.

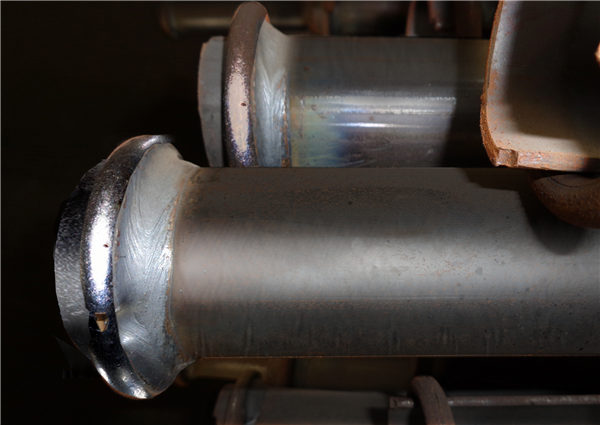

Welds on black bolt show the weld quality of our bolt, which is completely reached the highest international standard, and all of it is based on our strict quality management control (GMC), and quality and safety accident alerting system which already accompanied with production processes, to make sure a consistant and stable quality all throught the production.

Zinc coating inspection will be checked from time to time to keep the coating reached customer requirements, and has a smooth and average coating split set bolt surface. Packing is same as other main ground support split set bolt (friction bolt stabilizer) which is 150 units per pallet. Wooden and Metal Pallet are both available.

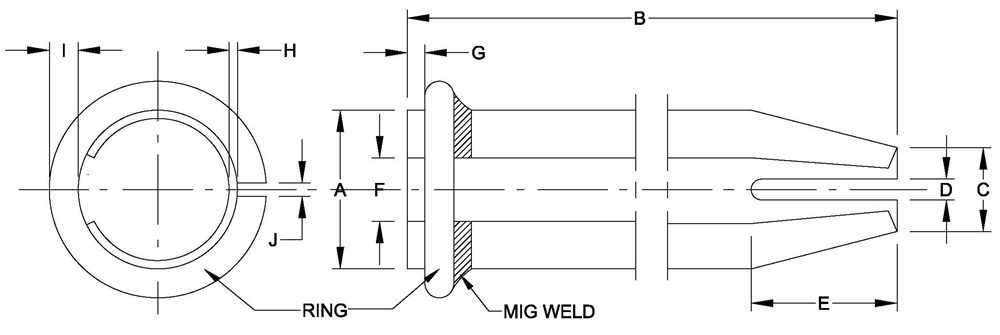

FB-39 SPLIT SET BOLT SPECIFICATION AND MECHANICAL PROPERTY

| Dimensions | Physical Properties | Technical Data | ||||||||||

| Bolt Diameter | A | 42mm | Yield Strength | Min. 345 Mpa (85KN) | Recommended Normal Bit Size | 38-41mm | ||||||

| Bolt Length | B | 0.9-3.0m | Typical 445Mpa(110KN) | |||||||||

| Taper End Diameter | C | 35mm | Tube Ultimate Tensile Strength | Min. 470 Mpa (115KN) | Typical Breaking Capacity | 124KN | ||||||

| Taper Slot Wide | D | 2mm | Typical 530Mpa(130KN) | |||||||||

| Taper Length | E | 65mm | Mass per Meter | 1.92 Kgs | Min. Breaking Capacity | 89KN | ||||||

| Bolt Slot Wide | F | 20mm | ||||||||||

| Ring Location | G | 3mm | Cross Section Area | 245 mm² | Recommended Initial Anchorage | 3-6 Tons (27-53 KN) | ||||||

| Material Guage | H | 2/2.5mm | ||||||||||

| Ring Wire Guage | I | 6mm | Hole Diameter Range | 38-41mm | Ultimate Axial Strain | Typical 21% (Thk<16mm) | ||||||

| Ring Open Gap | J | 6-7mm | ||||||||||

| Code | Bolt Description | Diameter | Length | Surface Finish | Weight | Packing QTY/Pallet | Ring ColorID | |||||

| (mm) | (mm) | (Kgs) | ||||||||||

| FB42-0900 | Split Set Bolt 42-900 | 42 | 900 | Untreated | 1.70 | 150 | - | |||||

| FB42-1800 | Split Set Bolt 42-1800 | 42 | 1800 | Untreated | 3.23 | 150 | - | |||||

| FB42-2100 | Split Set Bolt 42-2100 | 42 | 2100 | Untreated | 3.76 | 150 | - | |||||

| FB42-2400 | Split Set Bolt 42-2400 | 42 | 2400 | Untreated | 4.30 | 150 | - | |||||

| FB42-3000 | Split Set Bolt 42-3000 | 42 | 3000 | Untreated | 5.37 | 150 | - | |||||

| FB42-0900G | Split Set Bolt 42-900 HDG | 42 | 900 | Hot Dip Galvanized | 1.80 | 150 | - | |||||

| FB42-1800G | Split Set Bolt 42-1800 HDG | 42 | 1800 | Hot Dip Galvanized | 3.38 | 150 | - | |||||

| FB42-2100G | Split Set Bolt 42-2100 HDG | 42 | 2100 | Hot Dip Galvanized | 3.94 | 150 | - | |||||

| FB42-2400G | Split Set Bolt 42-2400 HDG | 42 | 2400 | Hot Dip Galvanized | 4.50 | 150 | - | |||||

| FB42-3000G | Split Set Bolt 42-3000 HDG | 42 | 3000 | Hot Dip Galvanized | 5.63 | 150 | - | |||||

FB-42 SPLIT SET BOLT FEATURES

● As alternative main ground support bolt, FB-42 Split Set bolt is also made by High Tensile Steel, and different grade of material available depends on different use environment to save the cost of ground support.

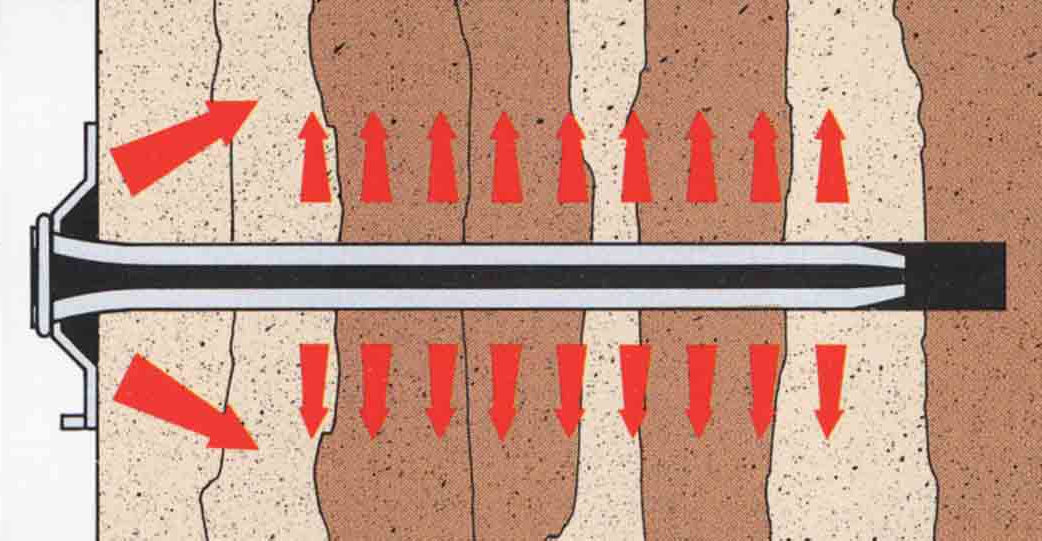

● By it's C shape body, it is also the most easy and effective way for ground support, to create an instant full length of friction force all the way to the rock, driving together with mesh and plate into the hole to get a quick ground support.

● Galvanizing and untreated Split Set Bolts are both available.

● Full range of accessories available.

FAQ of FB-39 SPLIT SET BOLT

1. What is Combi Plate and how does it make ?

The FB-42 Split Set Bolt are made by high tensile steel strip, which is roll-formed into a longitudinal slot C shape tube along its entire length. A steel ring is full welded on the end of the tube by automatic welding device, which is to hold the plates to the rock surface.

2. How to use and assemble ?

The tubular C shape of the bolt generates a load transfer from the steel to the rock when installed into a slightly smaller diameter hole, and results in a frictional resistance pull-out load of the tube from the hole, and creating a full length radial pressure to the hole by increasing the contact surface of the steel to the rock due to its tubular shape, and when install onto the plate, it establishes a compressive force against the rock. When additional load bearing capacity is required, friction bolt can be grouted by cement grouts.

2. How to use and assemble ?

A pull collar fixing at the ring end enables load testing during the bolt installation. The tapered end of friction bolt can be easily inserted into the drilled holes. Friction bolt can be installed with either hand held or mechanized equipment, such as a jackdrill, a stopper, a roof bolting jumbo, or any other type of drill.